Reflecting on The Great Recovery's partnership with Fab Lab London, Sophie Thomas explains why having circular economy thinking in makespaces provides the perfect combination for disruptive innovation.

At the end of September, with the city in the throes of its annual celebration of design (the London Design Festival), The Great Recovery Innovation Hub opened its doors at Fab Lab London.

This was a realization of a vision had some 2 years before when Nat Hunter and I were brainstorming what would bring about the kind of disruptive behaviour that was needed to bring about the circular economy.

The Great Recovery work to date had signalled to us that design was the creative stimuli needed to kick old business models and managers stuck in established pathways back into the innovation light. And so one day, at a café table, the visual sketch was drawn, like a yin-yang diagram of two worlds colliding: the hacked together and slightly revolutionary creative disrupters of the Fab Lab world and those that inhabited the business landscape, desperate for new ideas but not knowing where to turn.

These spaces aren’t new. The phenomenon of innovation hubs, fabrication hubs and make spaces have been around for a while; it’s the accessibility that is key. What is new is the articulation around circular economic thinking and redesigning that The Great Recovery brings to Fab Lab London.

I have been asked by several people why you need circular economy thinking in a Fab Lab. Here, in a nutshell, are my reasons:

1. Disruption

Feedback from businesses we work with at The Great Recovery mentions their need for ‘disruptive’ thinking and doing to shift the stagnant business-as-usual stalwarts to being able to see the opportunity. This needs different types of thinkers and creators, and Fab Lab members are pretty hot in this area.

2. Rapid Prototyping

Circular Economy at scale is an unknown quantity, and so rapid routes to market and fast prototyping are crucial. Designers and businesses need to print out, test, put together, take apart and bring to market quickly in order to get a fast, iterative design process going. If a product is to be redeveloped around a re-manufacturing model for instance, then speedy prototyping for component disassembly is a must.

3. Knowledge sharing

This is an obvious one and a key to successful circular activity. The Fab Lab guys know stuff that we don’t. It’s humbling to watch someone with technical know-how work, and it’s no wonder that businesses who are looking for innovation in circularity want some of this expertise. On the flip side, the Great Recovery is here to help increase understanding and awareness around sustainable thinking and circularity. Closing the loop through design isn’t easy to get your head around. Not only that, but you need to have a lot of the network of supply chain and end of life sitting around you when you do redesign things because more often than not it involves a complete system reboot. This is where our Circular Network comes in.

4. Longevity through fixing and customisation

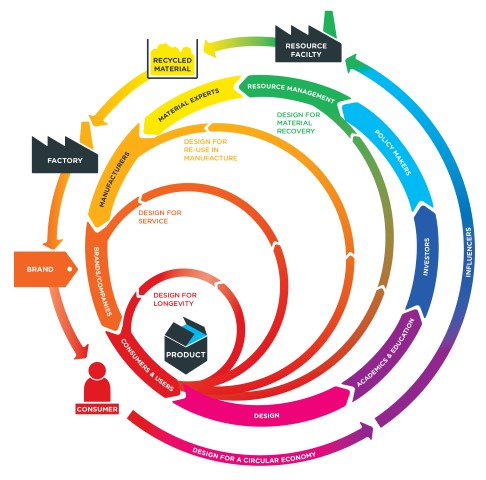

Encouraging re-use by fixing and hacking takes the circularity focus closer to the inner loop (see Four Design Models diagram below) where increased utilization of the product makes the most of the embodied energy from initial production. Rather than see a defunct product through a technical lens and immediately break it down to raw materials, as is often the case for those that work in this area, we can extend its use by hacking and fixing in the Lab. Our teardown and design up methodology promotes this, and we work with businesses and community groups like Restart and Bright Sparks to teach us where re-use value lies (as well as point out bad models of product obsolescence!)

FabLab have additive (3D printers) and reductive (laser cutter) printing kit which are also key for the circular designer. A new cooker knob can be open sourced and printed on a 3D autobot; a laser cutter can optimize your cutting for minimal material wastage (think getting the most out of cookie cutting) or customize your product for greater user attachment.

5. Re-thinking waste streams

In one of our very first videos for The Great Recovery, our facilitator Mark Shayler talked about a product being a transient moment in time for the materials stream that flows around the economic system. This insight is the basis for our process of tear down and design up. Working with those that ‘hack’ electronics is eye opening in that they see the space between. For them opportunity lies in the component building blocks –part of a washing machine that can be reutilized in urban aquaponics, a motorized unit from a broken printer can be used to create a 3D scanner. Where we see a broken down product and only scrap material value, the Fab Labbers may see valuable components that do specific and transferable tasks.

6. Unlocking information flows

Fab Labs are hotspots for Arduino and sensor technology development, and circular thinking needs this to help unlock the data flows that accompany our products. We can’t build solutions to waste reduction if we don’t know where things are and how long they stay there. In order to understand where our stuff is at any given moment, in order to get it back for reuse or repair, we need to develop some serious sensor-driven tracking data.

The Great Recovery programme is about networking and action, testing and piloting. This new Fab Lab space allows us to do just that, to bring together novices and experts, make open calls to those that want to learn about circular design, and create new models for the stuff all around us.

Be the first to write a comment

Comments

Please login to post a comment or reply

Don't have an account? Click here to register.